Umenzi wePCB okhuphisanayo

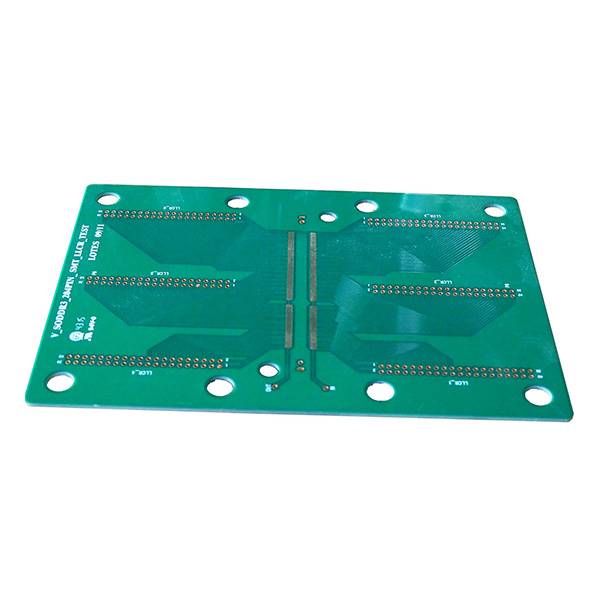

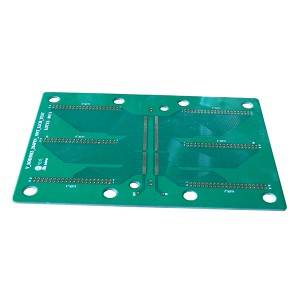

3 oz solder imaski ukuplaga ENEPIG ibhodi yobhedu enzima

Akukho nkcazelo isemgangathweni ye-PCB ye-Heavy Copper, ngesiqhelo ukuba ubukhulu bobhedu bungaphezulu kwe-30z.

Ibhodi ichazwa njengebhodi yobhedu engqindilili.

Ii-PCB ze-Heavy Copper zisetyenziswa kakhulu kwiinkqubo ze-Electronics zaMandla kunye noBonelelo lwaMandla apho kukho imfuneko ephezulu yangoku okanye kunokwenzeka ukudubula ngokukhawuleza kwesiphoso sangoku. Ubunzima bobhedu obongeziweyo bunokuguqula ibhodi ye-PCB ebuthathaka ibe yindawo eqinile, ethembekileyo, kunye nexesha elide le-wiring kwaye ligatya imfuno yeendleko ezongezelelweyo kunye nezixhobo ezinkulu ezifana ne-Heat sinks, abalandeli, njl.

Ukusebenza kwebhodi yobhedu engqindilili: ibhodi yobhedu eshinyeneyo inowona msebenzi ubalaseleyo wokwandiswa, awukhawulelwanga ngubushushu bokusebenza, indawo yokunyibilika ephezulu ingasetyenziselwa ukuvuthela ioksijini, ubushushu obuphantsi abunabungozi kunye nezinye i-welding eshushu enyibilikayo, kunye nothintelo lomlilo, yeye-non -izinto ezinokutsha. Iipleyiti zobhedu zenza i-copper eyomeleleyo, engeyiyo ityhefu, i-coat passivated, naphantsi kweemeko ze-atmospheric eziyingozi kakhulu.

Izinto eziluncedo kwipleyiti yobhedu eshinyeneyo: Ipleyiti yobhedu eshinyeneyo isetyenziswa kakhulu kwizixhobo zekhaya ezahlukeneyo, iimveliso zobugcisa obuphezulu, ezomkhosi, zonyango kunye nezinye izixhobo zombane. Ukusetyenziswa kwepleyiti yobhedu etyebileyo yongeza ubomi obude benkonzo yebhodi yesekethe eyona nxalenye ingundoqo yeemveliso zezixhobo zombane, kwaye kwangaxeshanye, luncedo olukhulu ukwenza lula umthamo wezixhobo zombane.

Ukwenziwa kweePCB zeCopper ezinzima

Nayiphi na imveliso ye-PCB, nokuba icala elinye okanye icala eliphindwe kabini liqulunqwe nge-etching yobhedu ukususa ubhedu olungafunekiyo kunye neendlela zokucwenga ukongeza ubukhulu kwiindiza, iipads, kunye nemikhondo kunye nePlated-Through-holes (PTH). Ukwenziwa kwee-PCB ze-Heavy Copper zifana nolwakhiwo lwee-PCB eziqhelekileyo ze-FR-4 kodwa zifuna iindlela ezikhethekileyo zokutsala kunye ne-electroplating eyonyusa ubukhulu bebhodi yomphezulu ngaphandle kokutshintsha ukubala umaleko. Iibhodi ezishinyeneyo zoMphezulu ziyakwazi ukuphatha iintsimbi ezongeziweyo zobhedu ngenxa yeendlela ezikhethekileyo ezibandakanya isantya esiphezulu, ukuzityabeka, kunye nokwahlula okanye ukutenxa.

Indlela eqhelekileyo yokuhombisa ayisebenzi kwi-PCBs ye-Heavy Copper kwaye idala imigca yomphetho engalinganiyo kunye nemida egqitywe ngaphezulu. Sisebenzisa iindlela zokucwenga eziphucukileyo ukuze sifumane imigca eNgqongileyo kunye neyona mida ilungileyo enomphetho ophantsi ongahoywanga. Inkqubo yethu yokongezelela i-plating inciphisa ukuxhathisa kweempawu zobhedu ngaloo ndlela iphucula amandla okuqhuba ubushushu kunye nokunyamezela kuxinzelelo lwe-thermal.

UkuNcitshiswa kokunganyangeki kwe-thermal kuphucula amandla okususa ubushushu kwisekethe yakho ngokusebenzisa i-thermal convection, conduction, kunye nemitha. Abavelisi bethu bakwagxile ekuqiniseni iindonga ze-PTH ezibonelela ngezibonelelo ezininzi ngokucutha ukubala umaleko kunye nokunciphisa i-impedance, ukuprintwa kweenyawo, kunye neendleko zokwenziwa ngokubanzi. Siyazingca ngokuba ngomnye wabenzi bePCBs ezifikelelekayo nezisemgangathweni kwihlabathi jikelele.

Nangona kunjalo, ezi PCBs zibandakanya iindleko eziphezulu kune-PCB eziqhelekileyo njengoko inkqubo yokubhala inamandla kwaye inzima. Izixa ezinkulu zeCopper kufuneka zipheliswe ngexesha lenkqubo ye-Etching. Kwakhona, inkqubo yokulambisa ifuna ukusetyenziswa kwe-Prepreg enomxholo ophezulu we-resin yokuzalisa izithuba phakathi kweendlela zobhedu. Ke, ixabiso lokuvelisa liphezulu kuneePCB eziQhelekileyo. Nangona kunjalo, siqeshe indibaniselwano yeBlue Bar Method kunye ne-Embedded Copper indlela yokubonelela ngebhodi ephezulu ngexabiso elifanelekileyo.

Ukusetyenziswa kweePCB zeCopper ezinzima

Senza kwaye sinikeze ezi PCBs apho kukho rhoqo okanye ngequbuliso sesichengeni kubushushu obuqinileyo bangoku kunye nolwandisiweyo. Amanqanaba agqithisileyo anjalo anele ukonakalisa i-PCB eqhelekileyo kwaye ubize imfuno ye-Heavy Copper ekwathoba isibalo somaleko, ibonelela nge-impedance esezantsi, kwaye yenza ukuba indawo encinci kunye nogcino lweendleko ezinkulu. Apha ngezantsi kukho iindawo ezithile kunye nezicelo ezisetyenziswa kwiiPCB zeCopper eziNzima:

• Iinkqubo zokuSasazwa koMbane

• Iimodyuli zeAmplifaya yaMandla

• Iibhokisi zokuSasazwa koMbane weMoto

• Ubonelelo lwaMandla kwiiNkqubo zeRadar

• Izixhobo zokuwelda

• Iinkqubo zeHVAC

• Izicelo zaMandla eNyukliya

• UKhuseleko kunye noNxibelelwano olugqithisiweyo

• IiNkqubo zoMbane zikaloliwe

• Abavelisi bePaneli yeSolar

Kwiminyaka yakutshanje, imfuno yezi PCB inyukile kwiZithuthi, uMkhosi, ikhompyuter, kunye nezicelo zolawulo lwemizi-mveliso. I-Kangna inamashumi eminyaka yamava ekuveliseni iiPCB ze-Heavy Copper ezikumgangatho ophezulu. Iinjineli zethu zeZakhono zizinikele ukuhlangabezana nemigangatho ephezulu kwaye zenze iiBhodi zePremium ezihlangabezana nolindelo lwakho lokusebenza kunye neenjongo zenzuzo. Siyaqonda ukuba uyilo lwe-PCB ye-Heavy Copper iza nezinto ezintsonkothileyo kwaye ngenxa yoko, sijongana ngokusondeleyo nayo yonke imibuzo kunye neenkxalabo phambi kokuqhubeka nemveliso.

Yintoni eyenza ukuba sikhetheke kukuba iibhodi zethu eziphuhlisiwe zidlula kwimijikelo eyahlukeneyo yokujonga umgangatho ngaphambi kokuba zinikezelwe kubathengi bethu. Isebe lethu lokulawula umgangatho wendlu liqinisekisa umgangatho we-PCB ye-Heavy Copper kwaye iqinisekisa ukuba imveliso yokugqibela idibana nomgangatho ogqwesileyo kunye nomngcipheko omncinci wokungaphumeleli kwesekethe.

IINDIDI ZEMVELISO

Gxininisa ekuboneleleni ngezisombululo zemong pu iminyaka emi-5.